Why Choose Automation Equipment Bearing Solutions for Your Business?

In today's fast-paced industrial landscape, Automation Equipment Bearing Solutions are essential for businesses aiming to enhance efficiency. These specialized components ensure optimal performance, reducing downtime and maintenance costs. Companies that invest in high-quality bearing solutions often see improved productivity and reliability in their operations.

The choice of automation equipment can significantly impact a company's bottom line. Reliability is crucial, as failures can lead to costly interruptions. Automation Equipment Bearing Solutions offer unique advantages, such as precision engineering and durability. However, not every solution fits every business need, prompting careful evaluation.

While many organizations embrace these innovations, some may overlook crucial aspects of these solutions. Are they really the best fit? Understanding the specific requirements of your machinery is essential. In making your decision, consider both the benefits and potential drawbacks. This reflection can lead to a more informed choice that optimally supports your operations.

Understanding the Importance of Automation Equipment Bearing Solutions

Automation equipment bearing solutions play a crucial role in various industries. These components ensure smooth operation of machinery. They reduce friction and wear, enhancing efficiency. In a factory setting, a malfunction can halt production. This underscores the importance of reliable bearings.

Choosing the right bearing is not always straightforward. There are numerous factors to consider. Load capacity is essential. Operating conditions such as temperature and humidity also matter. Sometimes, the standard option might not meet specific needs. This can lead to unexpected downtime.

Investing in quality bearing solutions pays dividends. They can improve the lifespan of equipment. This reduces maintenance costs over time. However, businesses must regularly evaluate their equipment's performance. Reflecting on operational challenges can lead to better decisions. Automation equipment bearing solutions are vital for operational success, but they require careful consideration.

Key Benefits of Implementing Bearing Solutions in Automation

Automation equipment bearing solutions offer valuable advantages for businesses looking to optimize efficiency. These bearings reduce friction and wear in machinery, enabling smoother operations. By improving the longevity of equipment, companies can reduce costs related to maintenance and replacements. This leads to enhanced productivity in the long run.

Implementing these solutions can enhance precision in automated tasks. With reliable bearings, machinery operates more consistently, minimizing errors. However, finding the right bearing for specific applications can be challenging. Companies sometimes overlook precise requirements, leading to selection mistakes. This can result in unexpected downtime or inefficient operation, highlighting the need for thorough evaluation.

Moreover, automation solutions can adapt to various environments, from factories to cleanrooms. They can withstand varying temperatures and contaminants. This adaptability makes them suitable for diverse industries. Nonetheless, businesses must regularly assess their needs as technology evolves. Keeping pace with new developments ensures that companies utilize the best solutions available.

Why Choose Automation Equipment Bearing Solutions for Your Business? - Key Benefits of Implementing Bearing Solutions in Automation

| Benefit |

Description |

Impact on Business |

| Increased Efficiency |

Automation equipment bearings can reduce friction and improve operational speed. |

Higher productivity and reduced cycle times. |

| Reduced Maintenance Costs |

Durable bearings lead to fewer breakdowns and less frequent replacements. |

Lower operational costs and better resource allocation. |

| Enhanced Reliability |

Quality bearings ensure consistent performance over time. |

Minimized downtime and increased trust from customers. |

| Versatility |

Suitable for various applications across multiple industries. |

Flexibility in operations and adaptation to market changes. |

| Improved Product Quality |

Consistent operation leads to better manufacturing precision. |

Higher customer satisfaction and reduced defects. |

Types of Automation Equipment Bearings and Their Applications

Automation equipment bearings are essential components for various industries. They ensure that machinery operates smoothly. Different types of bearings cater to specific applications. Knowing these types helps businesses choose the right solution.

One common type is the deep groove ball bearing. They are versatile and can handle radial and axial loads. This makes them ideal for electric motors and conveyors. Another type is the thrust bearing, designed for axial loads. These are crucial in applications like cranes and elevators.

Tips: Always consider the load requirements. An overloaded bearing wears out quickly. Regular maintenance extends bearing life. Look for signs of wear, like noise or vibration. These can signal a looming issue.

Another type is the angular contact bearing. These handle combined loads and are perfect for high-speed applications. However, they need precise alignment. Misalignment can lead to premature failure.

Tips: Perform alignment checks regularly. Ignoring this step can cost you later. Keeping an eye on lubricant levels is vital too. The right lubricant reduces friction and heat. This can save money in the long run.

Types of Automation Equipment Bearings and Their Applications

Factors to Consider When Choosing Bearing Solutions for Your Business

Choosing the right bearing solutions is vital for any business. High-quality bearings enhance operational efficiency. A report by the Bearing Manufacturers Association highlights that 70% of machine failures result from bearing issues. This statistic underlines the importance of selecting the right bearings to prevent costly downtime.

Consider factors like load capacity and environmental conditions. Bearings must withstand specific stress and temperatures. For instance, a facility operating in high temperatures may require specialized bearings. According to industry data, businesses often overlook lubrication needs.

Insufficient lubrication compromises bearing longevity.

Cost is another crucial factor. While cheaper options may seem appealing, they often lead to higher maintenance costs over time. Investing in reliable bearings can save resources in the long run. Many companies struggle to balance cost and quality.

They must ask themselves if they are prioritizing short-term savings over long-term reliability.

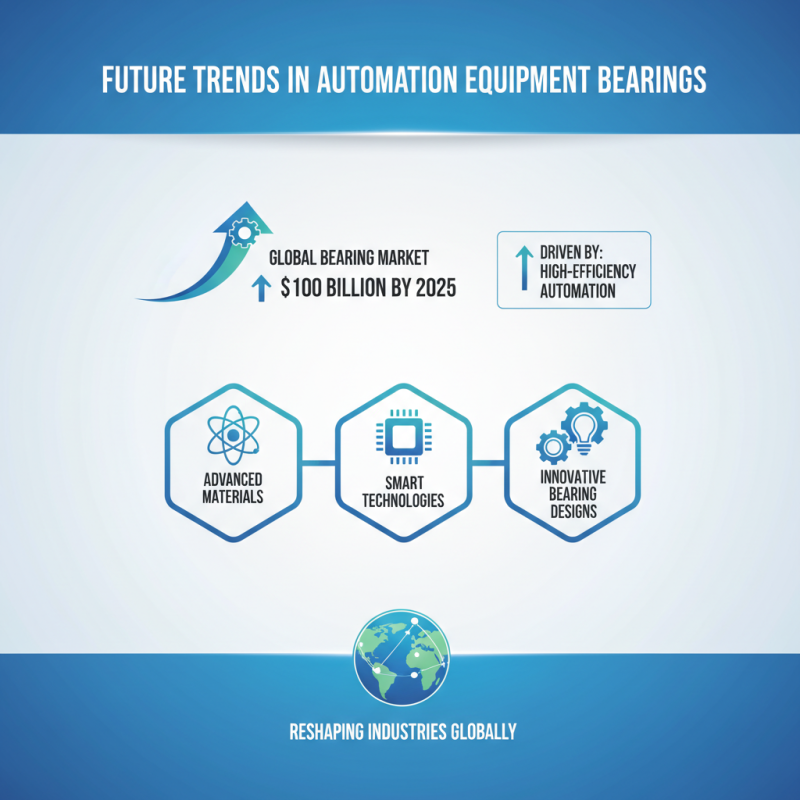

Future Trends in Automation Equipment Bearings and Their Impact on Industry

Future trends in automation equipment bearings are reshaping industries across the globe. Research indicates that the global bearing market will grow significantly, reaching approximately $100 billion by 2025. This growth is driven by increased demand for high-efficiency automation solutions in manufacturing processes. Advanced materials and smart technologies are paving the way for innovative bearing designs.

The integration of IoT and AI in bearing technology is also a key trend. Predictive maintenance techniques help companies reduce downtime and improve operational efficiency. Data from industry reports show that predictive maintenance can decrease maintenance costs by 20-30%. This technology allows businesses to foresee potential failures, ensuring smoother operations and long-term savings.

Tips: When selecting automation equipment bearings, consider their load capacity and speed ratings. Evaluate the environment where they will be used, as factors like temperature and humidity can affect performance. Always keep an eye on maintenance schedules to maximize lifespan. Remember, not all bearings are created equal; invest time in research to find the right fit.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us