Axles: The Backbone of Mechanical Mobility

Solid axles, which are continuous beams connecting wheels on either side of a vehicle, are renowned for their toughness. Designed for enduring stress and harsh terrain, these axles—like the Heavy-Duty Solid Axle With Integrated Braking System for Agricultural Vehicles—are commonly found in trucks, tractors, and off-road machinery.

Half axles serve as partial supports, often used in combination with other assemblies. The 3-Ton Agricultural Half Axle Assembly is one such example, providing necessary support while maintaining flexibility in configuration and load distribution.

In vehicles, axles are integral to both movement and structural integrity. Front axles contribute to steering and manage the weight of the engine compartment, while rear axles are primarily responsible for driving the wheels and supporting the vehicle's rear. These components must also withstand dynamic forces such as cornering and braking.

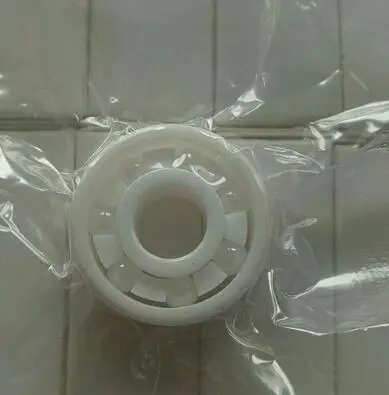

Modern automotive axles are fitted with bearings—usually tapered roller or ball bearings—to ensure minimal friction and optimal load-bearing. These precision components enable smoother drives and longer service life by efficiently managing both vertical and lateral forces during motion.

Beyond transportation, axles are indispensable in industrial settings. They are frequently used in material handling systems, such as conveyor belts, where they support rollers and assist in transferring goods across facilities. In rotating equipment like turbines or gear-driven machinery, axles must be precisely balanced and machined to ensure high rotational accuracy and durability under constant stress.

For example, in farming equipment, custom-forged axles allow for high-load performance and adaptability to various mounting systems, improving both efficiency and maintenance schedules.

The design of an axle begins with a careful analysis of its operational environment. Parameters such as maximum load, torque transmission, operating speed, and safety factors all influence the design. Engineers often opt for alloy steels known for their high yield strength and excellent resistance to fatigue.

Production involves several key stages:

·Forging, to shape the raw material under high pressure.

· Machining, to attain tight tolerances and optimal alignment.

· Heat treatment, such as quenching and tempering, to enhance surface hardness and structural strength.

These processes ensure that axles can perform under extreme mechanical and environmental stress.

Maintaining and Diagnosing Axle Issues

Routine inspection and maintenance are essential to extend the lifespan of axles. Common checks include looking for signs of excessive vibration, corrosion, or misalignment. Lubrication, particularly in high-speed applications, is critical to reduce wear on the bearings and axle surfaces.

Some warning signs of axle issues include unusual noises during acceleration or turning, and irregular tire wear patterns. In commercial vehicles, advanced diagnostic tools are now used to monitor axle temperature, rotational behavior, and alignment in real-time.

Innovations Shaping the Future of AxlesFinal ThoughtsAs industries push toward greater efficiency and smarter technologies, axle systems are evolving. One growing trend is the shift toward lightweight materials, such as aluminum alloys and composite hybrids, aimed at reducing vehicle mass and improving fuel efficiency.

In parallel, smart axle systems are emerging, equipped with integrated sensors that monitor load, thermal conditions, and vibrations. These systems can feed data into onboard diagnostics, enabling predictive maintenance and minimizing downtime.

Another development is the use of modular axle designs, allowing for easier customization and quicker replacements, particularly in logistics and agricultural sectors where machine availability is crucial.

Final ThoughtsThough often overshadowed by more prominent components, axles remain critical to the function and durability of mechanical systems. Whether ensuring stability in industrial machines or transmitting torque in a high-performance vehicle, axles underpin much of the modern world’s mobility and mechanization. As technology advances, the humble axle continues to adapt, promising even greater performance and intelligence in the years to come.